Rubber compression stress relaxation Tester distribute|stress relaxation experiment : suppliers The Wallace Compression Stress Relaxometer (WAC11) allows the operator to easily measure the Compression Stress Relaxation (CSR) characteristics of elastomers and rubber products (e.g. seals, O-rings) as required by the .

Renata Godi0 pictures and videos on EroMe. The album abo.

{plog:ftitle_list}

Resultado da Ontem 00:54:14 Big Brother Big Brother - Última Hora - 27 de fevereiro de 2024. Veja os melhores conteúdos do universo TVI e da CNN Portugal, em direto e on-demand. As novelas, os programas, o entretenimento. Big Brother, Dois às 10, Goucha.

Compression stress relaxation (CSR) testing: considerations in an era Of ISO 17025 proficiency testing. Paul Tuckner, Grace Technology & Development. In looking at .Measuring stress relaxation of rubbers in compression is a key test that is used to . Combined experimental results clearly present nonlinear elastic properties, time-decay relaxation, and unrecoverable damage deformation of rubber materials. The numerical .Stress relaxation testing measures when a constant stress creates a physical and/or chemical change in a plastic or rubber material, thus reducing the force that the polymer compound can .

linking will show if testing intermit-tent stress relaxation, which is in fact measuring the change in stiffness of the material. The cross linking will also clearly show when doing com-pression .The Wallace Compression Stress Relaxometer (WAC11) allows the operator to easily measure the Compression Stress Relaxation (CSR) characteristics of elastomers and rubber products (e.g. seals, O-rings) as required by the .

Measuring stress relaxation of rubbers in compression is a key test that is used to estimate the long term sealing behavior and performance life of seals, o-rings and gaskets.Reducing of stresses in rubber – stress relaxation is a joint expression of the elastic and viscous properties of the material. We apply the generalized Maxwell model or it has another . Accurate CSR testing for predicting rubber seal performance and longevity. Wallace Instruments, one of the most recognised and trusted brands of testing equipment for the global rubber industry, announces the launch of its .

Product Download. If you want to download this product information Please click here. Rubber, vulcanized or thermoplastic -Determination of stress relaxation in compression at normal and at. elevated temperature. ISO3384. Technical . In the present work, the localized stress of vulcanized rubber during a compressive stress relaxation test (i.e., ASTM D6147) was evaluated. Hyperelastic behavior .

Rubber stress relaxation models are the main material input data for numerical and analytical conveyor belt indentation rolling resistance calculations. Stress relaxation data for rubbers, such as those used in the construction of conveyor belts, are difficult to measure directly due to their fast relaxation times and, as such, they are usually derived via a dynamic .Our rubber and plastic testing experts have years of experience conducting accelerated aging testing to industry standards and custom specifications. Common Standards for Stress Relaxation Testing. ASTM D6147—Standard Test Method for Vulcanized Rubber and Thermoplastic Elastomer—Determination of Force Decay (Stress Relaxation) in CompressionCorrelation Between Compression-Set and Compression Stress-Relaxation of Epichlorohydrin Elastomers ©SmithersRapraTechnology,2011 1. INTRODUCTION Compression stress-relaxation is considered to be the most direct measure of the sealing capacity of an elastomer. It gives the force a rubber article would exert on a solid

Therefore, the current continuous compression stress relaxation (CCSR) test aims to offer an improved method of evaluating rubber compounds. ARDL Continuous Compression Stress Relaxation Test. The ARDL CCSR apparatus is shown in Figure 1a and Figure 1b. It consists of 5 fixtures placed inside a temperature chamber. 5.2 The ability of a material to relax at high-stress concentrations such as are present at notches, inclusions, cracks, holes, and fillets can be predicted from stress-relaxation data. Such test data are also useful to judge the heat-treatment condition necessary for the thermal relief of residual internal stresses in forgings, castings, weldments, machined or cold .Rubber, vulcanized or thermoplastic — Determination of stress relaxation in compression — Part 1: Testing at constant temperature . Caoutchouc vulcanisé ou thermoplastique — Détermination de la relaxation de contrainte en compression — Partie 1: Essais à température constante . This is a preview of "ISO 3384-1:2011".

Compression stress relaxation (CSR) testing: considerations in an era Of ISO 17025 proficiency testing January 26, 2021 April 12, 2021 RubberWorld 3792 Views. Paul Tuckner, Grace Technology & Development. . and has been the primary driver for many of the requirements in rubber testing. Many of the test requirements created for this market . Standard Test Method for Vulcanized Rubber and Thermoplastic Elastomer—Determination of Force Decay (Stress Relaxation) in Compression . (Stress Relaxation) in Compression D6147-97R20 ASTM|D6147-97R20 . download and distribute hard copies of Documents for training Authorized Users or groups of Authorized Users. (e) . Considering the different stress relaxation mechanisms reported in the literature (Abu-Abdeen, 2010, Mohammad and Mohammadian-Gezaz, 2011, Maria et al., 2014), the stress relaxation observed in the first few seconds of the test (pair A 1 and τ 1) occurred mainly due to the rupture of highly stressed rubber chains (rubber matrix contribution .The Compressive Stress Relaxation Test (DIN) ISO 3384-1 describes two methods for determining stress relaxation under pressure. In addition, the American SAE J 2979 also defines tests for compressive stress relaxation. An elastomer specimen is compressed with a constant load and the force it exerts against this external influence is measured.

the commencement of that time-interval. (Stress relaxation is a synonym.) 4. Summary of Test Method 4.1 Method AÑThe test specimen is compressed at the test temperature, and it is maintained at this temperature through-out the test period, all force measurements being made at the test temperature. 4.2 Method BÑThe test specimen .

The findings can give the localized phenomena of vulcanized rubber during a stress relaxation test, which can be used as a guideline for the design, usage, and improvement of rubber and viscoelastic polymeric components. . In each level of compression, the stress relaxation tests were repeated 3 times, and their average was used for the .Rubber, vulcanized or thermoplastic - Determination of stress relaxation in compression - Part 1: Testing at constant temperature This document specifies two procedures for determining the decrease in counterforce exerted by a test piece of vulcanized or thermoplastic rubber which has been compressed to a constant deformation and maintained .

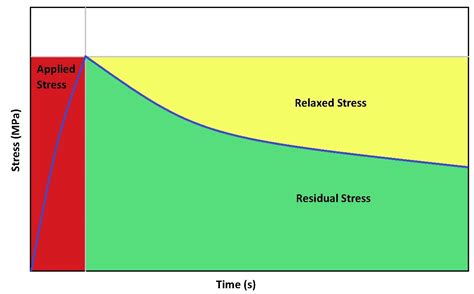

given time during a stress relaxation test. 3.1.5 relaxed stress—the initial stress minus the remaining stress at a given time during a stress relaxation test. 3.1.6 stress relaxation curve—a plot of the remaining or relaxed stress as a function of time. 3.1.6.1 Discussion—A curve to demonstrate that the stress relaxation behavior can be .were detached for compression set test and stress relaxation test at 25% strain levels individually at room temperature for every selected time. The test procedure follows the GB/T 7759.1-2015 and GB/T 1685-2008 standards. The data obtained in this study may be used to investigate the effect of different operating conditions, acids,Rubber, vulcanized or thermoplastic — Determination of stress relaxation in compression — Part 1: Testing at constant temperature

stress relaxation testing

but decreases with time; this behaviour is called “stress relaxation”. Conversely, when rubber is subjected to a constant stress, an increase in the deformation takes place with time; this behaviour is called “creep”. Tests in compression are normally made under continuous stress conditions (i.e. the test piece remains The compression properties of silicone rubbers used as gaskets in PEM fuel cells are studied. The specimens are aged under different test conditions, viz, high temperature, humid air, and acidic solutions, prepared to match real PEM fuel cell operation conditions. The compression and stress relaxation tests are conducted. Temperature, humid air and acidic .Tensile Uniaxial Creep Testing on Metallic Materials. Creep, Creep-Rupture, and Stress-Rupture Testing of Metallic Materials: Standard Test Methods per ASTM E139; The European Standard for Testing Metals, Part 005: Continuous Creep and Stress-Rupture Testing EN 2002-005; Stress relaxation testing of materials and structures according to ASTM E328

Compression Stress Relaxation (CSR) continues to be an important attribute in the evaluation of materials and seal configurations for their ability to provide sealing force retention under a range of conditions. . Citation: Tuckner, P., "Compression Stress Relaxation Testing - Comparisons, Methods, and Correlations," SAE Technical Paper 2001 .

Figure 2. Stress Strain curve of the instantaneous elastic response of the rubber defined by means of a Neo-Hooke strain energy potential. 2. Figure 3 shows the time-dependent behaviour of the rubber evaluated though a stress relaxation test at 5% strain. The material will be modelled with a linear Specifying Conditions for Compression Stress Relaxation Testing of Rubber and Thermoplastic Elastomers 90A or Less active, Most Current Buy Now. Details. History . Specifying Conditions for Compression Stress Relaxation Testing of Rubber and Thermoplastic Elastomers 90A or Less Introduction Note: Nothing in this standard supercedes .given time during a stress-relaxation test. 3.2.4 spherometer, n—an instrument used to measure circu-lar or spherical curvature. 3.2.5 stress-relaxation curve, n—a plot of either the remain-ing time or relaxed stress as a function of time. 3.2.6 stress-relaxation rate [FL−2 T–1],n—the absolute value of the slope of the stress .are recorded. The stress relaxation of rubber can usually be described through power law model M = k (t)a (1) where: M = torque units from the Mooney stress relaxation test, k = a constant equal to torque 1 s after the rotor has stopped, and a = an exponent that measures the rate of stress relaxation. The Eq.

The extracellular matrix and most tissues are stress relaxing, and the kinetics of stress relaxation have been recognized as an important mechanical cue that affects the migration, proliferation, and differentiation of embedded cells. [2] Stress relaxation calculations can differ for different materials: To generalize, Obukhov uses power .ASTM D1414 also defines a tension set test and a compression set test. These are stress relaxation tests. These tests can be performed in manual clamp fixtures; or they can be performed on the same versatile TestResources universal . This guide outlined the main areas of rubber testing, from natural rubber testing to mechanical testing, with specific details for 30 individual test methods and procedures, including details of the accompanying international test standards.

thick client application performance testing

thick client application performance testing tools

WEB17 de abr. de 2021 · Códigos de recursos. Los siguientes trucos le darán una infusión de recursos cada vez que los agregue y se pueden usar tantas veces como desee: 1000 x Madera: CABALLO TROYANO EN VENTA. 1000 x comida: NOCHE DE COMIDA BASURA. 1000 x oro: ATM DE EREBUS. Favor máximo: MONTE OLIMPO.

Rubber compression stress relaxation Tester distribute|stress relaxation experiment